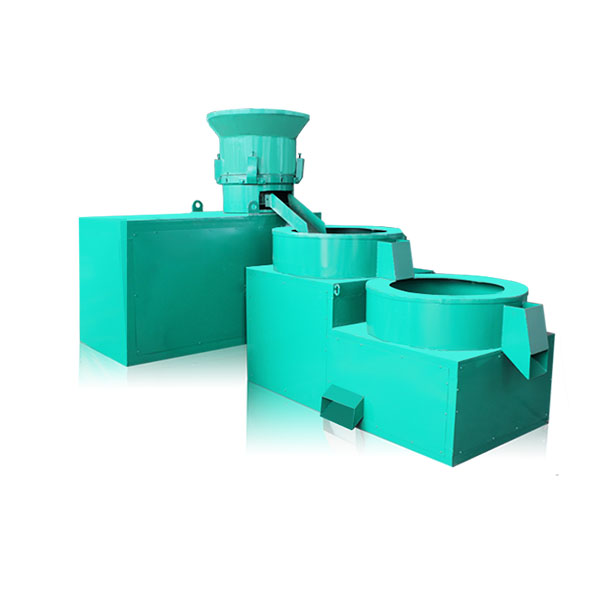

Product Description

Flat die pellet machine, also called flat die press granulator, Adopting the direct transmission form, can process various powdered materials into cylindrical particles (or cylindrical particles can be further shaped and rounded into spherical particles by polishing machine).

It has the characteristics of saving power, low power consumption, no vibration, high output, and low noise

Application

This machine is mainly used for particle processing in the (biological) organic fertilizer and livestock processing industries, or other powders that want to be made into particles.

Technical Data

| Model | Power(kw) | Capacity(tph) | Pellet dia.(mm) | Granulation rate | Pellet temperature |

| SFP400 | 30 | 1.5-2.5 | 3-10 | ≥95 | ≤25℃ |

| SFP600 | 55 | 2.5-4 | 3-10 | ≥95 | ≤25℃ |

| SFP800 | 75 | 4-7 | 3-10 | ≥95 | ≤25℃ |

Flat die pellet machine Advantage

- Organic matter can reach as high as 100%, which achieves the goal of pure organic fertilizer

- No binding agent is needed during granulation

- The pellets are strong and can be screened after granulation immediately, which can reduce the drying rate and energy consumption.

- The press wheel can be adopted, and the speed of the two ends is consistent with the die plate and the outer ring line, and there is no dislocation friction between the wheel and the die. The resistance is reduced, the kinetic energy loss is reduced, the service life of the die is prolonged, and the production cost is reduced.

- Press rollers are uniformly and closely set and smooth operation and the suppression area is increased to improve production efficiency.

- A screwing center adjustment pressure structure is adopted, the clearance of the die can be big or small to best granulate different materials and ensure the pressing effect.

- The pellet size can be ranged from Φ1.5mm to Φ20mm to adapt to different materials granulation, and finally achieve the best benefits.