Product Description

A new type of special granulator for organic fertilizers, it is used to granulate various organic raw materials after fermentation especially materials with much fiber. It does not need to dry the raw materials before granulation, and can directly batch ingredients after crushing. The mechanical stirring force of the high-speed rotation of the granulator and The resulting friction force enables the powdery material to be continuously mixed inside the machine, granulated, spheroidized, and strengthened to achieve the purpose of material granulation. The water content of raw materials can be granulated at about 30%-40%. The finished particle diameter is generally between 0.3-5 mm, and the granulation rate is >85%.

Application

It can be applied to chicken manure, pig manure, cow manure, sheep manure, carbon black, clay, kaolin and other light fine powder,especially used to granulate various organic raw materials after fermentation especially materials with much fiber.

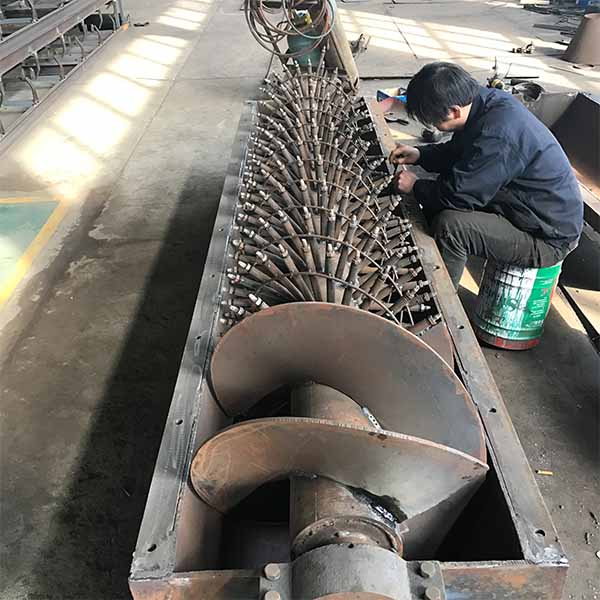

Granulation Principle

The working principle is that the material enters the machine from one end of the feeding port, and is continuously pushed and mechanically moved with the machine casing through the granulation rotor. By utilizing the high-speed rotating mechanical stirring force and the resulting friction force, the powdered material is continuously mixed, granulated, spheroidized, and strengthened inside the machine, achieving the purpose of material granulation.

The size of particle diameter can be adjusted appropriately by the material mixing amount and spindle speed. Generally, the lower the mixing amount, the higher the speed, and the smaller the particles, and vice versa.

Technical Data

| Model | Power(kw) | RPM | Capacity(tph) | Size/L*W*H(mm) | Weight/(kg) |

| SFG-60 | 37 | 312 | 1-2 | 3710*960*1060 | 1400 |

| SFG-80 | 45 | 242 | 2-3 | 3710*1260*1310 | 2800 |

| SFG-100 | 55 | 373 | 3-4 | 3780*1450*1510 | 4500 |

| SFG-120 | 75 | 450 | 4-5 | 4960*1800*1900 | 6800 |

| SFG-150 | 90 | 578 | 5-6 | 5200*2300*2150 | 9200 |