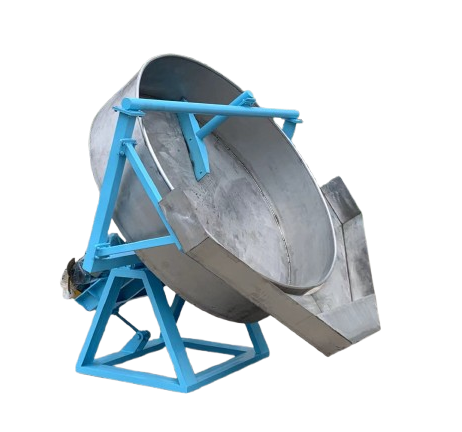

Product Description

Pan granulator, also called disc granulator, are the types of equipment for converting powdered materials into round granules. also, it is one of the key granulation equipment in the compound fertilizer and organic fertilizer industry

Pan granulators utilize a non-pressure (tumble growth) approach to agglomerate and work by tumbling material on a rotating pan, with a binding agent and feedstock being continuously added. The binding agent causes the fines (or seed pellets when utilizing a pre-conditioning step) to become tacky and pick up additional fines as the material tumbles against itself. This causes a “growing” action referred to as coalescence. Once pellets have reached the desired size, they exit the rotating disc via centrifugal force.

Granulation Principle

The belt pulley and belt are driven by the main motor, and the pinion is driven by the reducer. The pinion and the big gear fixed at the bottom of the plate are engaged with each other to work in the same direction. The big gear is installed on the main shaft fixed on the rack adjustment plate through a special and reasonable design to support the work of the entire pelletizing disk (this machine is used in conjunction with the spray). After the materials enter the pelletizing disk, they are rotated continuously by the pelletizing disk and the spray device, The material is uniformly bonded together to form spherical particles. An automatic cleaning device is designed in the upper part of the granulation plate of the machine to prevent material from sticking to the wall, greatly improving the service life of the machine. With the continuous rotation of the motor and the continuous entry of materials, batch production can be achieved, which meets the needs of continuous operation.

Technical Data

| Model | Disc dia.(mm) | RPM | Volume(m3) | Power(kw) | Capacity(tph) |

| SFY10 | 1000 | 24 | 0.4 | 2.2 | 0.3-0.5 |

| SFY15 | 1500 | 22 | 1.1 | 3 | 0.5-0.8 |

| SFY18 | 1800 | 18 | 1.4 | 5.5 | 0.6-1 |

| SFY20 | 2000 | 18 | 1.8 | 7.5 | 0.8-1.2 |

| SFY25 | 2500 | 18 | 2.5 | 7.5 | 1-1.5 |

| SFY28 | 2800 | 18 | 3.3 | 11 | 1.8-2.5 |

| SFY30 | 3000 | 16 | 3.9 | 11 | 2.5-3.5 |

| SFY32 | 3200 | 13.6 | 4.3 | 15 | 3.5-5 |

| SFY36 | 3600 | 11.3 | 5.5 | 22 | 5-6 |

| SFY45 | 4500 | 8 | 6.5 | 30 | 8-10 |