- HOME

- ABOUT US

- SOLUTION

- PRODUCTS

- Fertilizer granulator machine

- Organic fertilizer compost fermentation machine

- Fertilizer crushing machine

- Fertilizer blending machine

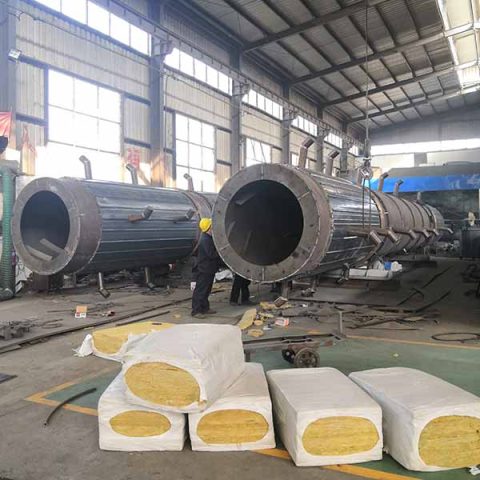

- Fertilizer drying machine

- Fertilizer cooling machine

- Fertilizer screening machine

- Fertilizer coating machine

- Fertilizer packaging machine

- Dosing system or weighting scale

- Fertilizer additives

- BLOG

- CONTACT US