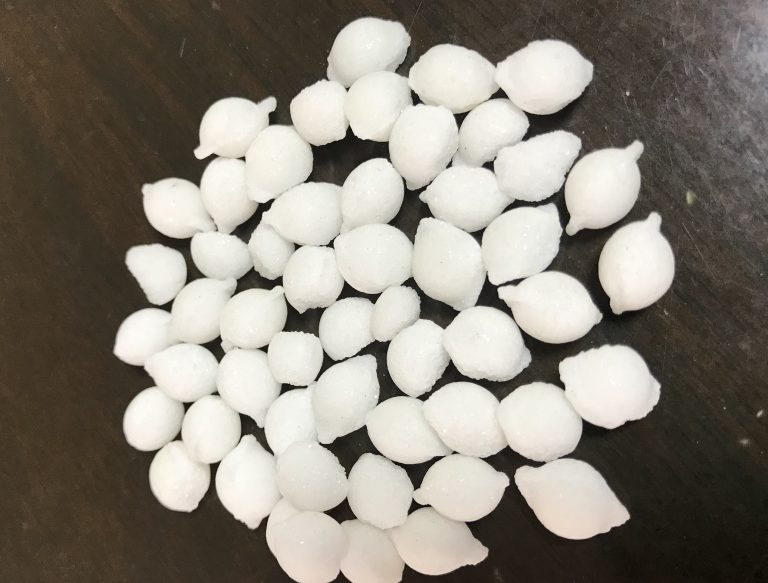

Double roller extrusion granulator, which is the most recommended granulation equipment in fertilizer production, can directly press powdered materials into granules at room temperature, with the functions of high strength and little pollution during the process. it is widely used in granulation of ammonium chloride, ammonium sulfate, potassium chloride, potassium sulfate, various formula compound fertilizers, water-soluble fertilizers, functional fertilizers, organic-inorganic compound fertilizers, water purifiers, snow melting agents, etc.

However, some points must be noted to achieve the best granulation effect during the roller press granulator.

1. Requirements of the raw material itself: brittleness, hardness, wear resistance, density

Take urea and super phosphate as examples. When mixed with a low content, they can act as a binder, because when pressed them they tend to soften. However, when the content exceeds a certain amount, it will become soft. Only after a long period of aging for a better granulation process.

The hardness of the raw material determines the force and energy consumption required for extrusion and granulation.

The wearing resistance coefficient is the main reason of the surface wearing of the roller. Recommend to use special steel when granulate wear-resistant materials.

The density of the raw material determines the appearance density of the granules and the production capacity of the machine.

2. Environmental characteristics of the raw material, such as: bulk density, humidity, temperature, particle shape, particle size range, and material flowability

The size of the raw material powder is recommended to be less than 200 mesh.

The humidity generally does not exceed 8%. Different materials have different humidity requirements.

3.Characteristics of the machines, such as: extrusion force, roller speed.

Zhenghou Safi Machinery Co.,ltd. Have more than 13 years experience in powder granulation machine and kinds of fertilizer processing machines.

Any questions, feel free to cotact us.

Zhengzhou Safi Machinery Co.,ltd.

www.safimachinery.com

Email:carter@safimachinery.

Whatsapp:+86 15238391768

Wechat:15238391768